High-quality, full customisable and bespoke GRP moulding and GRP production services

Alongside GRP / fibreglass production and mould making, we also provide other GRP services such as model and pattern making, tool making and prototyping.

Everything at Amusement Technical’s GRP factory is done by hand by a highly skilled team of GRP experts, completing your finished product to a very high standard.

Our design team use a combination of software and traditional methods to tailor designs to your exact specification.

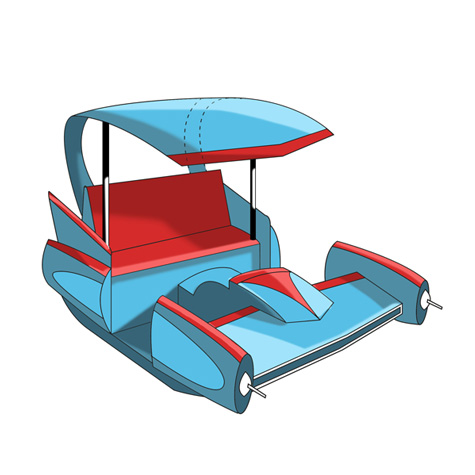

At Amusement Technical, we understand the importance of the ride vehicle design and theming succeeding in captivating a visitor’s imagination and fit in perfectly with a park area’s theme.

Our GRP services tend to be turnkey for our clients – we design, manufacture, install and repair.

The mould is the most critical aspect of the manufacturing process, as it dictates the surface finish and ease of reproducing the product in the future. The GRP mouldings we produce are sustainable and of the highest quality to ensure they are reusable.

We are one of the few GRP producers that still use the Hand Layup Process which generally produces more intricately designed and stronger moulds than those that are machine made. This fits very well with the theme park industry which requires low volume but complex GRP moulds. Through a step-by-step process involving a mould release agent, a gel-coat, a resin, a reinforcement, rolling and curing, our open mould laminating process creates the smoothest of finishes on our GRP mouldings.